The brain of every robot/manipulator is its control unit, compact and powerful, designed to operate as a stand-alone system or integrated, usable as a simple positioner or a complete program for IAI, fully programmable for EPSON, TM and NACHI.

IAI control units

The operation of single-axis and multi-axis (up to 6) systems is orchestrated, according to the needs of the individual application, by two possible families of controllers:

The “CON” family

Basic controllers that communicate the desired position coordinate by recalling one of the stored positions in memory by an external management device (PLC)

The “SEL” family

Advance controller from the IAI family programmable using the simple SEL language: positions can be recalled and I/O can be activated autonomously in the sequence set within the controller or by interpolating movements on multiple axes without the need for a PLC. Easy even for beginners.

Controller EPSON

RC90

Compact and lightweight.

Small, intelligent and extremely efficient, equipped with an RS-232C serial interface, 24/16 standard I/O, 1 Ethernet port and integrated Modbus protocol as standard. It provide the flexibility to expand its capabilities with specific expansion boards for communication with various fieldbuses on the market, all at a reduced price.

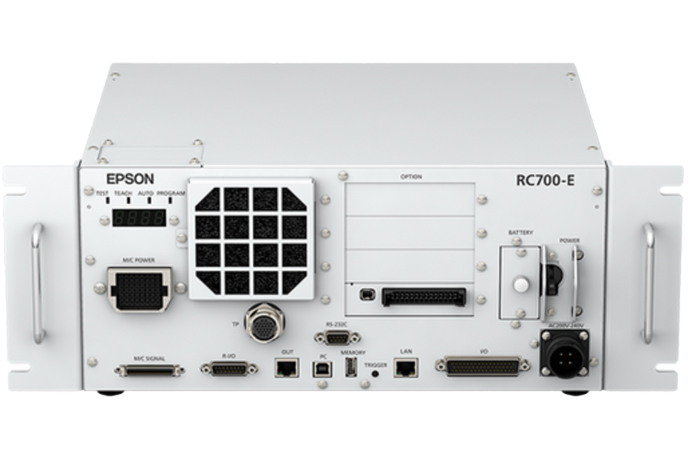

RC700-E

One for all

Compact and powerful it manage different types of EPSON robots and controlling their movement.

It features an open and customizable architecture: it can communicate with all conventional fieldbuses, as well as peripherals such as sensors, conveyors, actuator without the need of a PLC.

TM control unit

Compact, comprehensive and intuitive the TM control Box features an LCD display that shows the robot’s status and any issues.

Equipped with standard I/O 16/16, RS-232, three Ethernet ports and the Modbus protocol for communication with external devices, it also has an HDMI port and USB ports for managing it like a PC (or remotely). Communication with conventional fieldbuses is also possible.

NACHI control unit

The operation of the robots is orchestrated according to the needs of the individual application by two possible families of controllers:

The CFDs family

Compact, high-performance, it is the smallest controller in its category in terms of dimensions: 310mm wide x 250mm deep x 160mm high, thus saving precious space. The CFDs Controller is the nerve center designed to offer precise and flexible control of NACHi robots with payloads up to 12kg. It has an intuitive teach pendant interface, is equipped with a touchscreen and JOG dial. This controller supports a wide range of hardware and I/O connectivity options, including additional servo axes (7th and 8th axis), I/O cards and fieldbus cards. It also includes advanced functionality for force sensors and the management of conveyor tracking applications. The CFDs integrates functions such as High-Speed Interference Detection and Collision Detection, ensuring reliable and safe operations. Thanks to its 220V power supply, it guarantees low energy consumption..

The FD family

The FD20 controller is the ideal solution for those seeking precision, safety, and versatility in the operation of NACHI robots with payloads starting at 25 kg. Designed to be the heart of the robotic system, it offers advanced features that optimize every aspect of operation.

The monitoring unit provides cutting-edge safety control, monitoring motor power, operating limits, and speed to prevent accidents. Thanks to a wide range of fieldbus options (such as DeviceNet, CC-Link, PROFIBUS, EtherNet/IP, PROFINET, CC-Link IE Field, and EtherCAT), the FD20 integrates seamlessly with any network infrastructure and external devices. Whether spot welding, handling, palletizing, or sealing, the FD20 can be configured for your specific needs.

It is managed by FDonDesk: this offline robotic programming software allows you to accurately visualize and test every movement of your robot program, a highly recommended step to ensure safety and precision before operating the actual robot. With FD on Desk, in fact, you can verify programs created with the programming language for the robot controller directly from your PC, ensuring flawless execution and minimizing risks.

DRAWING

To support you we provide you with the technical drawing of some controllers